Marine Steel Wire Rope Sling And Socket

Marine Steel Wire Rope Sling And Socket

Marine wire rope is essential in marine industries as it plays a crucial role in mooring, towing, deck engine provision liftboat winch crane ,elevator , lifting, and lowering equipment, as well as in drilling operations and fishing activities. The wire rope’s strength, durability, and resistance to corrosion make it an ideal material for these applications.

There are several types of marine wire rope available, each designed for specific marine applications. Here are some of the most common types: non rotating, ungalvanized , stainless, sling wire rope,nylon coated galvanized aircraft cable,Plastic-Coated Wire Rope, stainless steel wire rope, galvanized steel wire rope,ungalvanized steel wire rope,steel wire rope supplier, steel wire ropes and so on.

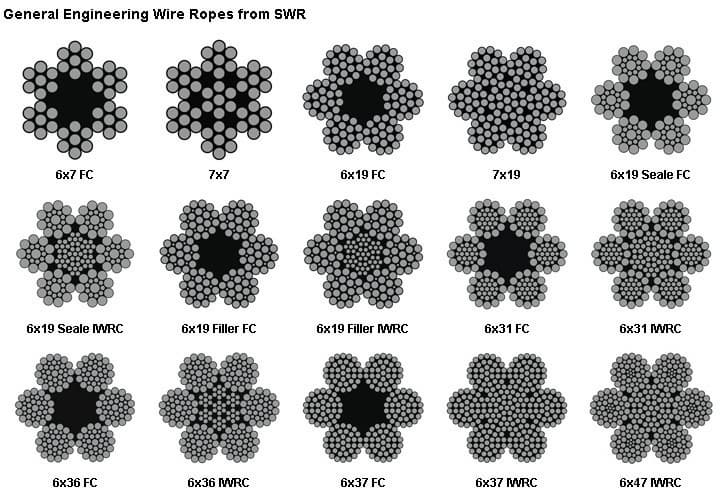

the popular wire rope :6x19W+IWR ,6x19W+FC ,6Vx19+FC ,6×19S+FC,6×19S+IWR,6×19+IWR,6X24S+7FC ,6X24W+7FC,6x36WS+IWRC (6x36WS+FC) ,1x7, 1x19,6x19 ,6x7 ,6X37+IWR ,6X37+FC ,6X37WS+FC

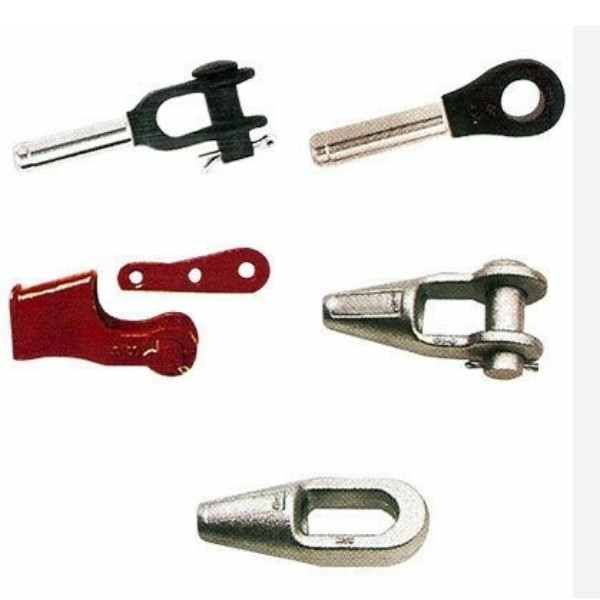

There are many different types of sockets: open and closed spelter sockets, open and closed swage sockets, wedge socket and Nemag rope pear socket.

Spelter socket and Nemag rope pear socket are secured to the rope with Wirelock socketing agent, and the rope retains its full strength.

The Nemag rope pear socket when paired with the Nemag quick release link forms an unbreakable connection between two ropes. Together, they enable quick and straightforward coupling and uncoupling of grabs on cranes. Made from high grade austenitic manganese steel, these Nemag fittings generally outlast the wire rope.

Our sockets are made of high quality cast steel supplied in hot dipped galvanised finish and comply with EN10204 3.1/3.2, JIS F3432 or RR-S-550D, Type B standard.